Over the past few decades, we’ve witnessed a revolution in how factories operate. From steam engines in Industry 1.0 to automation and data in Industry 4.0, the focus has often been on speed, efficiency, and technology. But now, a new wave is rising—Industry 5.0, and at its heart is the human being.

While Industry 4.0 emphasized the Internet of Things (IoT), artificial intelligence (AI), and automation, Industry 5.0 shifts the spotlight back to people, promoting collaboration between humans and machines. This new paradigm prioritizes not only productivity but also human well-being, creativity, and sustainability.

What is Industry 5.0?

Industry 5.0 refers to the next stage of industrial evolution, where humans and intelligent machines work together to create personalized and sustainable products and solutions. It’s not about replacing humans with robots; it’s about enabling humans to work better with them.

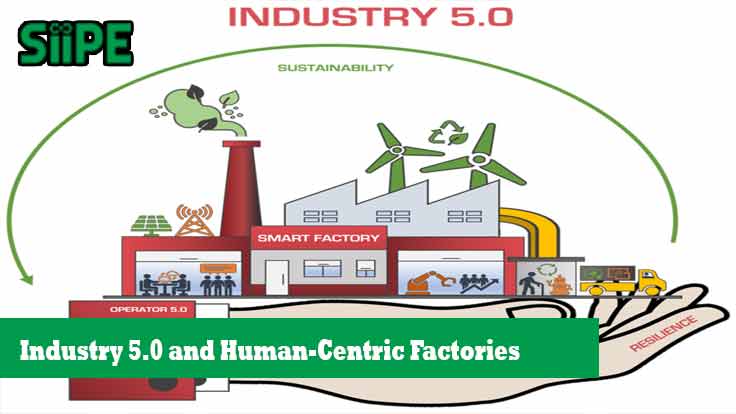

Instead of focusing solely on technological advancement, Industry 5.0 introduces three core pillars:

-

Human-centricity

-

Sustainability

-

Resilience

This marks a fundamental shift in mindset—from pure efficiency to meaningful impact.

The Role of Human-Centric Factories

Human-centric factories are at the center of Industry 5.0. These are manufacturing environments where human skills, creativity, and intuition are enhanced—not replaced—by advanced technologies.

In these factories:

-

Cobots (collaborative robots) work alongside human operators.

-

AI systems assist in decision-making, but the final judgment remains human.

-

Workers have more control over their tasks and more opportunities for innovation.

This approach improves both employee satisfaction and product quality.

Why Industry 5.0 Matters Now

The world is facing complex challenges: climate change, geopolitical instability, economic inequality, and post-pandemic recovery. Industry 5.0 offers a framework to address these challenges by rebalancing the focus between profit, people, and the planet.

Here’s why it’s important:

-

Mental Health and Workplace Safety: Automation can reduce physical strain, while human-centric design ensures less cognitive overload.

-

Customization Demand: Consumers today demand highly personalized products. Humans, with support from AI, can deliver on that need better than machines alone.

-

Sustainability Pressures: By combining human oversight with automation, manufacturers can adopt more eco-friendly practices.

Key Technologies Driving Industry 5.0

While Industry 5.0 emphasizes humans, it still relies on powerful technology to empower them. The key technologies include:

1. Collaborative Robots (Cobots)

Unlike traditional robots that work in isolation, cobots are designed to operate side-by-side with humans. They handle repetitive or heavy tasks, allowing humans to focus on more complex and creative work.

2. Artificial Intelligence (AI) and Machine Learning (ML)

AI systems help workers make better decisions by analyzing vast data in real time. For example, in quality control, AI can highlight potential defects while humans decide on corrective actions.

3. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR can assist workers in training, maintenance, and complex assembly tasks by overlaying digital information on the physical world.

4. Digital Twins

A digital twin is a virtual replica of a real-world system. It allows operators to simulate, test, and improve manufacturing processes before applying changes in the real world.

Real-World Examples of Industry 5.0

Several companies around the world are already embracing Industry 5.0 principles:

-

BMW uses AI to help workers identify issues on the assembly line, while cobots handle physically demanding tasks.

-

Siemens integrates AR to support technicians in field service, reducing downtime and training time.

-

Festo, a German automation company, combines bionics and robotics to mimic nature and support human capabilities.

Benefits of Industry 5.0

✅ Higher Job Satisfaction

By freeing workers from repetitive tasks and allowing them to focus on meaningful work, companies can improve employee morale.

✅ Greater Innovation

A human-centric environment encourages creativity and problem-solving, leading to better products and services.

✅ More Sustainable Production

With humans involved in critical decisions, it’s easier to implement ethical and environmentally friendly choices.

✅ Improved Customer Experience

The ability to personalize products quickly and efficiently gives companies a competitive edge.

Challenges to Industry 5.0 Adoption

Despite its promise, transitioning to Industry 5.0 has its challenges:

-

Resistance to Change: Employees and managers may resist new ways of working.

-

Skill Gaps: Workers need training to operate in human-machine collaborative environments.

-

Cost of Implementation: Advanced technologies like cobots and digital twins require significant investment.

-

Cybersecurity Risks: Increased connectivity also brings new vulnerabilities.

Companies must approach this transformation with clear planning, inclusive leadership, and continuous education.

Q&A: Understanding Industry 5.0

Q: Will Industry 5.0 take away jobs like Industry 4.0?

A: Not necessarily. Industry 5.0 focuses on collaboration, not replacement. It aims to create meaningful jobs rather than eliminate them.

Q: How does Industry 5.0 affect small manufacturers?

A: Small manufacturers can benefit significantly by adopting modular and scalable technologies. It allows them to personalize products without massive infrastructure.

Q: Is Industry 5.0 only for advanced economies?

A: No. With cloud computing and affordable automation tools, even emerging economies can implement Industry 5.0 principles incrementally.

Industry 5.0 is not just a technological revolution—it’s a human revolution. It brings back the human touch in an increasingly automated world. In this new era, machines don’t take over; they empower us to be more creative, agile, and responsible.

Human-centric factories that embrace Industry 5.0 are the future of resilient and sustainable manufacturing. They don’t just produce more—they produce better, for people and the planet.